The quality of the technologies we have is what makes the difference.

The production area developed over 14,000 m2, 7,500 m2 covered, 600 m2 of warehouse.

The production area developed over 14,000 m2, 7,500 m2 covered, 600 m2 of warehouse.

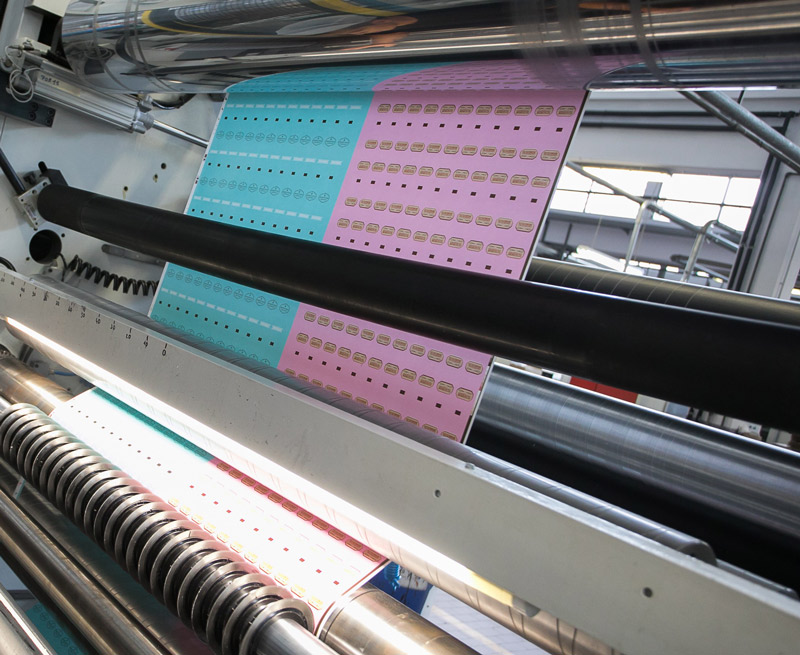

PRINTING DEPARTMENT:

Three colors rotogravure machines (6-8-10 colors) guarantee a very high result on paper, plastic films, aluminum and nylon.

The quality of the completely printing process is been optimized thanks to the purchase of the Bobst RS6003 HS 10 color printing press.

The RS6003HS is equipped with an integrated 100% print defect control system which, together with the control of off-line color shades (through high quality densitometers / photometers recognized on the packaging market) guarantees excellent print quality, in addition to an ESA system that ensures greater printability on shades and half-shades.

Bobst press is also equipped with a double airflow drying system, which makes the process more efficient. Front and backside printing, drafting of matt / tactile paints as well as full or register bottom solders, film and metalized tractors.

About 6 and 8 colors rotogravures the print defect control is guaranteed by an off-line visioning machine with 100% inspection system which automatically signals and catalogs all defects. Both roto 6 and 8 colors are equipped with an integrated ESA system.

LAMINATION AND PARAFFIN DEPARTMENT:

A solvent less laminator is into our department to guarantee work peaks and to meet requests for laminates up to 1500 mm of useful range.

Lamination is a delicate and very important process, and for this reason, Casalini performs careful tests about weldability, spreading adhesive weight, traction and solvent residue.

CUTTING DEPARTMENT:

– Six cutters on reels band from mm.20 to mm.1500.

– Two sheets cut in different formats.

CYLINDER WAREHOUSE:

It contains our customers catalogued printing cylinders

RAW MATERIALS WAREHOUSE:

Well supplied to guarantee and satisfy customers’ storages and requests

QUALITY CONTROL LABORATORY:

To guarantee a constant and on-line verification of all processing phases, monitoring and analysis of the incoming raw materials and the finished product. It has advanced technologies and equipment to meet customer requirements and guarantee the current regulations for product safety.

N. 1 gascomatografo – n. 1 dynamometer – n. 1 welding machine – n. 2 precision balances – n. 1 thickness gauge – n. 2 photometer spectrum – n. 1 densitometer spectrum – n. 1 barcode reader – n. 2 light benches.